This article is written with the purpose of analyzing how chips and LED technology have evolved over time, and how LedsUniverse has been working on designing the LED structure that could, very shortly, become the reference for the future (the bond between Flip Chip and Eutectic Solder).

This type of structure would result in a hybrid technology, somewhere in-between the current Flip Chip LED approach and the Eutectic welding method (Eutectic solder). LedsUniverse is looking at the possibility of upgrading the way chips and frame are connected, by leveraging on the advantages that result when both of these two technologies come together, and, when combining them, we are simultaneously able to cancel off the shortcomings they face when standing separately.

This mix would generate the most stable and reliable method of binding LED chip and frame into one. In short, we are blending two quite commendable technologies, in a purified new one, in which the best characteristics of each of them would be retained and co-exist; in short, we would be creating the most perfect LED technology available in the market.

In order to explain all of this well, it is therefore important to have an overview on the LED chips evolution, over 3 perspectives: past, present and future.

In the Past

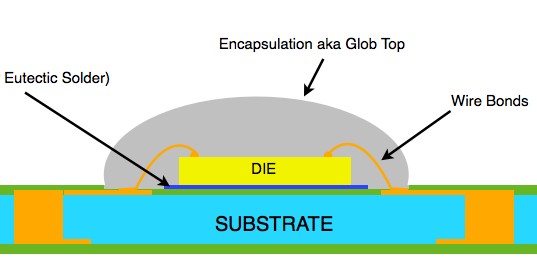

Earlier on, LED chips were connected to the frame by the usage of conventional glue, and through a gold wire that would link them to the nearby frame. The traditional gold wire bonding method was not very efficient because the structure employed in this arrangement triggered low thermal ability and heat resistance levels.

Today

1. FC (Flip chip) LED Process

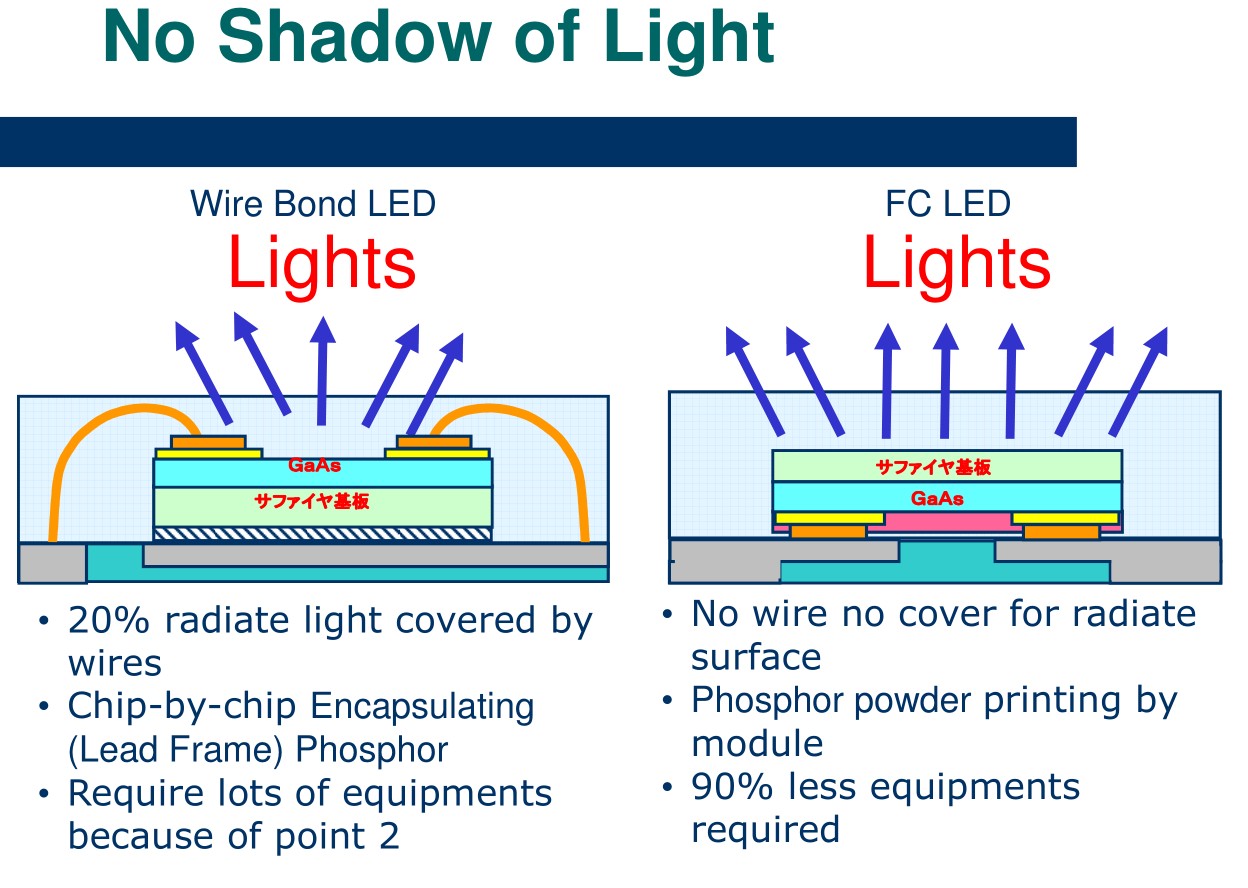

Nowadays there is a new patented technology known as the FC (Flip chip) LED technology, which basically consists in installing the LED chip upside down (therefore why it is called “flipped”), and directly solder it on top of the frame, without the need of using a gold wire. Basically, in this technology the LED chip itself is acting as the bridge between the lead frame(s), and therefore replacing the older gold wire method.

The Flip-Chip technology brought some benefits to LED because it increased the speed of the overall production process (making it more reliable and stable), but also decreased the thermal resistance levels, which in turn, lead to a faster, higher and more efficient heat dissipation system solution.

Some of the advantages of this technology included:

a. Lighter heat sinking because dissipation occurs at a much faster pace than before

b. Lower production costs, because the heat sinks do not need to be as robust as they were under the wire bonding technology

c. Longer LED lifetime and very low decay levels (roughly 3% at 6000 hours)

d. Improved reflective brightness, without shadowing effects

Even if there are many advantages in this technology, there is also a drawback, which lies in evaluating if the chips’ bottom has been perfectly soldered against the frame. And the only way to determine if the connection is faultless, is by the means of using a supersonic device during testing.

2 – Eutectic Welding LED Process (Eutectic solder)

In this Eutectic solder method, the new welding platform created enables the adoption of electromagnetic waves in order to perform fast heat that carries out chip eutectic welding.

In this Eutectic solder method, the new welding platform created enables the adoption of electromagnetic waves in order to perform fast heat that carries out chip eutectic welding.

By welding in such a way, the alloy material connecting the LED chip to the frame will become an integrative part of the chip and the frame, creating a very solid bond between both. In this scenario, heat resistance is lower.

However, in this approach there is also a disadvantage, which is the fact that the gold wire still exists, so the lights still suffer from issues related with heat efficiency and resistance to impacts or vibration.

Future

What we are trying to achieve is developing a Flic-Chip technology that instead of using normal soldering, would use Eutectic Welding (Eutectic solder). In this way we would be able to eliminate any gold wire installation, as well as avoid the supersonic solder test, while improving the heat dissipation flow, and the anti-vibration endurance of the LED lights.

In short, we would be creating a new and perfect technology, resulting from the combination of the Flip-Chip and the Eutectic Welding methods.