For a factory where products get manufactured, packed and delivered; having just enough lighting is not sufficient. Lighting that illuminates the workspace properly, according to the standards set by the competent authorities can be called proper lighting. There have been many studies and researches that show the ill effects of improper lighting in a workspace, reduced concentration span, low productivity, dizziness, etc. are few of them. Due to improper factory lights, not only the production will be slow but there can be many production and assembly defects in the end product. Dull lighting is definitely a problem but having extra bright lights is also a big problem because of the glares that it will produce. Bright lights will make the machines shine and it can result in deterioration of the focus of the workers. Before setting up a factory, there are many things which need to be thought and proper lighting conditions is most important of them.

In order to make a conducive working environment, there are some salient features that a factory should definitely take care of –

Factory Lighting Features

1. Ability to Function Round the Clock

A factory is a place where there is always something going on. There are shifts in day and night, which require proper lightings. A Factory is a place that has engagements round the clock. The lighting infrastructure there should be such that it should be able to illuminate the premises without the need for any break. It should never produce heat in a large amount because if it does so, then it will need to be switched off to let it cool down. The type of lights should be chosen considering the operational time. Also, if the power supply goes off, then also the lighting should be energy efficient enough to operate on the auxiliary power arrangements.

2. Able to Withstand High Temperatures

There are many factories like hot mills, steel manufacturing units, etc. which have very high operating temperatures and the lighting setup should also be able to withstand the heat and work efficiently. These industrial units require industrial level lighting equipment because of the drastic temperature fluctuations that it will have to bear. There are different types of casings available in the market that if fitted around the lights, can save the equipment and help them to work normally.

3. Flexible Lighting Plan

Many times, there is a need to change the position of machines and also to add new machines according to production demands. The lighting design should be flexible so that it can adapt to different layouts in the factory, if needed.

4. No Fluorescent Lights in Food Processing Industry

Fluorescent lights are definitely not a good choice for food processing units because of the mercury content inside it. There are chances that the mercury can leak into the food ingredients when fluorescent tubes are broken. The results can be dangerous. Since food safety is an issue of prime concern that’s why fluorescents lights should not be used as factory lights for food processing units.

5. Color Rendering Index for Quality Control

Color Rendering Index is a vital element of quality control because it provides a sense of color to the viewer. A high color rendering index refers to accurately perceiving the colors of the articles. It is very important to maintain a high CRI to obtain industrial standards. Normal offices with computer jobs can have lower CRI because of their nature of job but a factory needs to have proper lighting conditions to ensure the quality of end products.

6. Easy Maintenance Quality

The maintenance of the factory lights should be easy and should not involve a lot of manpower. The lights should be fitted such that it is easy to reach and cleaning doesn’t require sophisticated equipment for it.

7. Energy Efficiency

Whatever lighting setup is done, it should be energy efficient otherwise it will ultimately increase the production cost and will result in lower profits that’s why one should choose energy efficient options like LED Lights for their workspaces. By upgrading the lighting of a firm to a more energy efficient infrastructure like LED factory lighting, it is also contributing to a greener tomorrow.

Advantages of LED Factory Lights

The industry is opting for a greener tomorrow by upgrading to LED lights. Not only LED lights have greater energy efficiency but they also come with many other advantages like –

1. Life Span

LEDs have a longer lifespan as compared to metal halides and halogens. Metal halides usually have a lifespan of 2-3 years but on the other hand, LEDs can last up to 30 years.

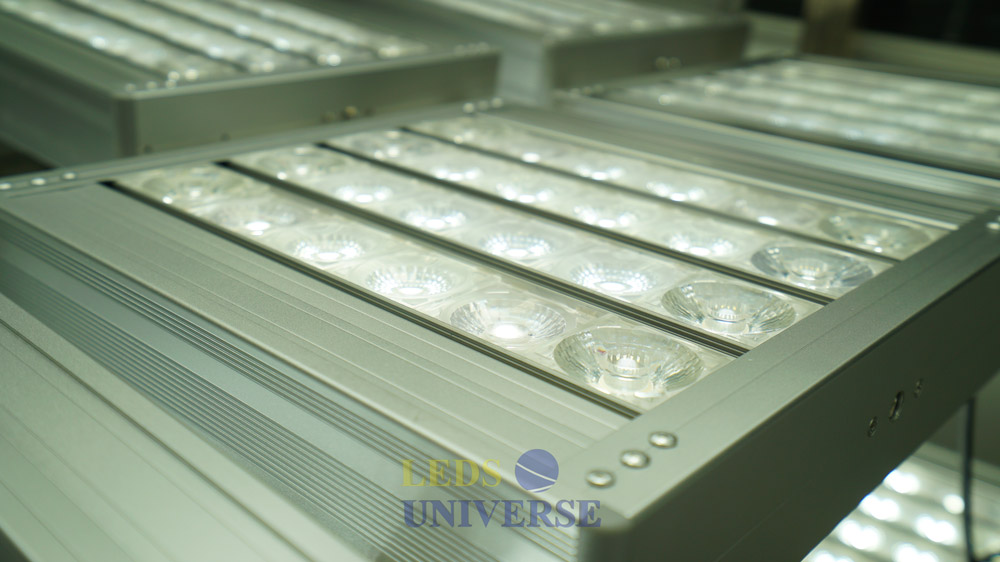

2. Physically Small Size

Due to the working principle of LED lights, they come in small sizes. Even high-intensity lights can come in compact sizes, which is a plus point for manufacturing units.

3. Low Maintenance

LED lights don’t need constant care from you as is the case for metal halides. The surface can be cleaned if the light accumulates dust over it.

4. Zero UV emissions

LED lights produce very little amounts of infrared rays and almost 0 UV rays. LED lights therefore, can be used in those facilities which produce products that are sensitive to UV rays.

5. Greater Color Rendering Index

LEDs have a very high rating. The rating for LEDs ranges from 65-95 which is very good for quality control purposes.

6. Tremendous Design Flexibility

Due to the small size, the design can be customized and made according to the factory needs.

7. Lower Heat Generation

Due to the working principle on which the LEDs work, it has significantly lower heat generation, which is very vital in increasing the operational time and life span of the equipment.

8. Instant Lighting and Frequent Switching

LEDs can be made to use instantly after switching on and can be switched on and off frequently without any issue.

Conclusion

LEDs can save a lot of money in the production and will also prove to be beneficial in illuminating the factories in the required proper manner. Your one step in lighting up gradation can change the atmosphere of your workplace and increase the efficiency of the workers. It will also reduce the number of accidents that happen due to ill lighting conditions and will ultimately save many lives.